- 0086-0576-84399766

- vip@yinglangmold.com

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Mold Flow Analysis)

5. MasterCAM (CNC Program)

6. Unigraphics (CNC Program)

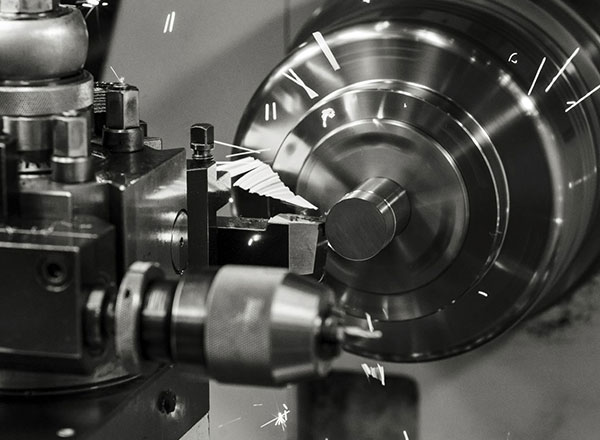

7. CNC Machining Center

8. CNC EDM's (Electric Discharge Machining)

9. Wire Cutting Machine

We have many years of experience in the production of plastic molds. From mold design to mold testing, we offer complete in-house services and are your first choice for plastic mold manufacturers in China. We are managed by professional staff with complete technology and years of experience. We have many first-class equipment such as CNC, EDM, engraving machines, wire cutting machines, etc. We use the latest CAD / CAE / CAM, which not only guarantees the quality of the mold, but also improves the efficiency.

In the spirit of openness and enthusiasm, Yinglang has extensive contacts with experts and customers in the field. Research, study, and cooperation to invigorate the industry.

(1) Vernier caliper, micrometer, thick/thin plug, spiral gauge.

(2) Hardness tester, temperature gauge and color chart.

(3) Toolmaker microscope, surface plate。

(4) Three coordinate measuring device.

Before we deliver products to our customers, each of us must pass the relevant quality inspection process to achieve the perfect standard.